- Home

- Products

Advanced Auto Doffing Systems

Advanced Auto Doffing Systems

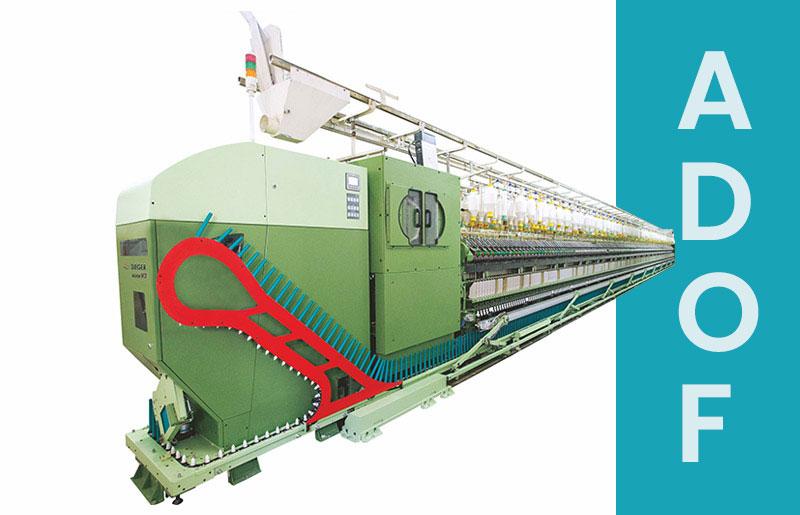

AUTO DOFFER RETROFIT – ADOF

- Advanced doffing system with shortest doff time of < 90 seconds.

- Hopper for random dumping of empties , to reduce manpower.

- Unique top bunching and under winding to control restarting breaks to < 2 % .

- PLC based restarting breaks control system.

- Flexi gripper to ensure 100% removal of full cops and insertion of empties .

- Mechanism with simple kinematics to reduce cost of maintenance.

ADOF V3 - Automatic Doffing System

A State of the art doffer with many innovative technologies from a dedicated and sustained R&D of Sieger.

Shortest Doff Time*

Advanced doffing mechanism with shortest doff time of <90 seconds.

Dumping System

Random dumping of empty bobbins. Feeding is effortless which ensures drastic man power reduction.

Unique Top Bunching Mechanism

Unique top bunching mechanism to save manpower. Upto 25% increase in bobbin feeding efficiency @ auto corner.

Flexi Press Gripper

Unique gripping with spring assisted bobbin presser. A must for spindles with spring button.

Under Winding

Positive control of under winding ensures very less start up breaks.

Detachable Caddy Peg

Effective value engineering ensures drastic reduction in maintenance cost.

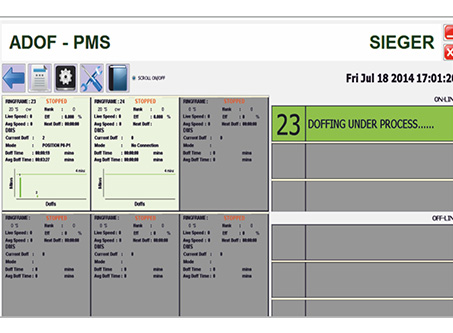

Production Monitoring System

State of the art integrated data information software. Complete spinning real time data at your table.

Ball Screw with Encoder

Efficient lifting and doffing mechanism with least power and compressed air compression - save electricity.