- Home

- Products

Yarn Conditioning Plant - NG UF - Pitless

Yarn Conditioning Plant - NG UF - Pitless

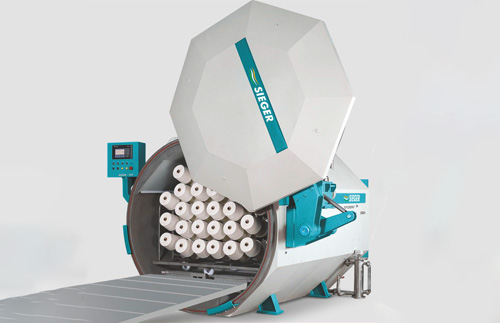

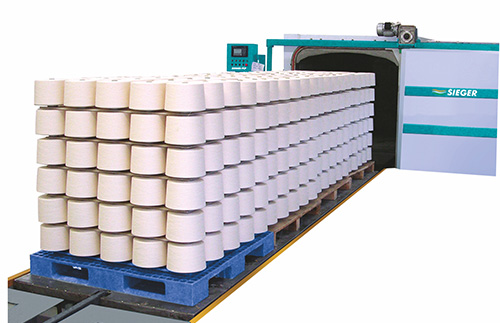

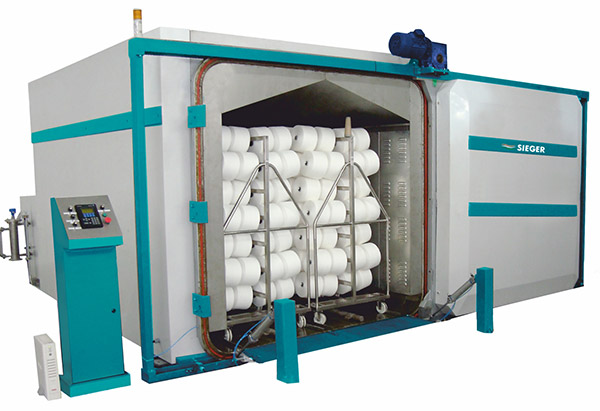

SIEGER Yarn Conditioning Plant - NG UF (Pitless)

| Description | NG-UF -600 | NG-UF -800 | NG-UF -1200 | NG-UF -1600 | |

| Capacity / Batch | Kgs | 600 | 800 | 1200 | 1600 |

| Production / Day | Ton | up to 13.80 | up to 18.40 | up to 27.60 | up to 36.80 |

| No. of Trolleys / Batch | Manual | Manual | Manual | Manual | |

| Heating Type | Std | Electric | Electric | Electric | Electric |

| Opt *-1 | Steam | Steam | Steam | Steam | |

| Opt*-2 | Gas | Gas | Gas | Gas | |

| Required Floor Space | L | 10,100 | 10,100 | 11,000 | 11,000 |

| W | 6,000 | 6,000 | 7,800 | 7,800 | |

| H | 2,330 | 2,330 | 2,500 | 2,500 | |

| Basic size of the Plant | L | 4,100 | 5,100 | 4550* | 4800* |

| W | 1,600 | 1,600 | 2,500 | 2,500 | |

| H | 2,400 | 2,400 | 2,600 | 2,600 | |

| Size of the Foundation | L | 6,100 | 6,100 | 5,000 | 5,500 |

| W | 4,000 | 4,000 | 5,000 | 5,500 | |

| Sliding Door | mm | 2500 | 2500 | 4600 | 4600 |

| Power (Peak Load) | Kw | 90 | 120 | 150 | 180 |

| Machine weight in Ton | Tons | 4.0 | 4.5 | 5.0 | 6.0 |

|

*Production / Day - Depends on capacity / batch & process parameters. *Capacity considering a standard package diameter 210mm & standard package weight 1.890 kgs. *Technical details given are subject to change without prior notice. |

|||||