- Home

- Products

Cone to Container - C2C

Cone to Container- C2C

C2C comprises of cone transport automation, cone image processing system, pallet forming, pallet transporting, hybrid conditioning with pre-conditioning and vacuum conditioning, de-palletizing, followed by packing of cones automatically in poly bags/sacks, carton boxes and pallets and automatically storing them in ASTOR (vertical storage) and delivering the material near the point of loading into containers.

C2C - YCP Auto Line

The state-of-the-art fully automatic YCP NG auto line has a pre & post condition system to impart right amount of moisture under controlled conditions resulting in consistent yarn quality. The YCP NG Auto Line with pre-conditioning is available in different capacities and in different layouts to suit the customer requirements.

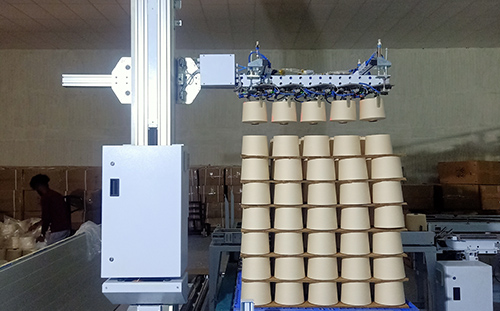

C2C - De-Palletizer (Robo)

DE Palletizer Robo picks up cones from Accumulator and arrange cone in pallet form.

C2C - APAC

Automatic Cone Packing System has modules for automatic wrapping of conical at cylindrical yarn packages in polythene film and packing them in HDPE bags or carton boxes.

C2C - ASTOR

ASTOR stores the Carton boxes/Cone bags & pallets through the yarn Warehouse Management System. The Automated Storage and Retrieval bases on ERP instructions

C2C - Loader

The Cone Transport System has motorized loader to collect the cones from the link auto-auto winding/Air jet/OE/vortex and load cone into the overhead cone transport system. Each cone line has one loader attached to it

C2C - Cone Transport System

The overhead cone transport system has a cone carrier to transport cones from the Link cone winding to the pallet-forming area.

C2C - Unloader

The Cone Transport System has a motorized unloader which collects the cones from the Overhead cone transport system and transfers them to accumulator. Each version need one unloader.

C2C - Accumulator

Cones carried by the CTS from link winding machines is identified by RFID and unloaded at respective servo controlled accumulator depending on the pallet configuration / number of cones. Each accumulator has one unloader,

C2C - Palletizer ( Robo )

Palletizer Robo picks up cones from Accumulator and arrange cones in the pallet form.

C2C - Pallet conveyor ( Motorized )

The Pallet conveyor is the location for placing the wooden pallets/plastic pallets (customer scope) where the pallets are formed. Depending on the different counts/lots produced in the mill, the number of pallets quantity is varied. (For 8 different counts, 8 pallet conveyors will be required).

C2C - Pallet / Separator Dispenser

The Pallet dispenser is an empty pallet storage system for stacking wooden pallets from where the pallets are dispensed to individual pallet conveyors on the removal of one full pallet.

The Separator dispenser is stationery set up for stacking the separator sheets, from where Robo will pick up sheets after the formation of one layer in the pallet.

C2C - IPS ( Image Processign System )

To detect cone tip identification, material mixup, yarn tail end missing, stained cone system and segregation, the detect cones separately

C2C - Transfer Shuttle ( Mobile )

The Transfer shuttle is a conveyor with a mobile arrangement to transfer the fully formed pallets from the pallet conveyor to the delivery turn table.