- Home

- Products

Automatic Over Head Travelling Cleaner

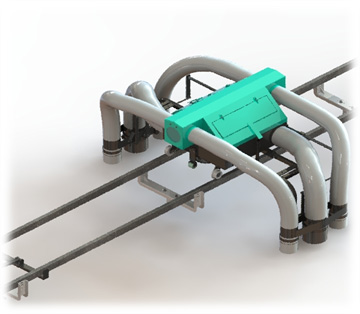

ATC - Automatic Over Head Travelling Cleaner

Principle of Automatic Over Head Travelling Cleaner

SIEGER Automatic Travelling Cleaner is the highly efficient Over head travelling cleaner for textile machinery with lower maintenance cost. The system is designed for higher blowing and cleaning performance.

Product Features

- Light weight and state of the art Aero Dynamic design with CFD for better performance and aesthetics

- Specially designed closed power duct – Longer life of hi-tech carbon brushes.

- Unique current collector design with self-cleaning arrangement.

- Base and face mounted motor to reduce vibration of the unit.

- Equipped with unique PLC for machine operation.

- Interlocking design for fan for better stability and performance.

Optional Features

- Auto parking

- Compact yarn suction and blowing arrangement

- Centralized collection system

- Obstacle sensor

- Blowing for bobbin transport system

Models Available

- Power duct with carbon brush for ring frames

- Belt type simplex and Auto/Link Coners

Technical data

| System | Power duct type |

| Fan motor | 2.2 kw, 415 Volts |

| Drive motor | 150 W, 1350 rpm |

| Blowing air volume | 3700 m3 / hour |

| Suction pressure | 200 mmwg |

| Travelling speed | 16 mpm. / 12 mpm. |

Models available : Power duct with Carbon Brush for Ring frames, Belt Type for Simplex and Auto / Link Coners.

SOLUTIONS

Cleaning Solutions offered by us

ATC – AUTOMATIC TRAVELLING CLEANER

Automatic Over Head Travelling Cleaner

In the manufacturing process of textile yarns & fabrics the modern machines are running at very high speeds and hence control of fly liberation and continuous evacuation of the liberated fly becomes more essential in order to maintain good quality, trouble free operation of the machines. A clean environment contributes to better performance and higher productivity, especially in a textile mill where fly liberation can have a direct impact on quality of output products.

SIEGER offers Over Head Travelling Cleaners for the following machinery:

- Speed Frames.

- Ring Frames.

- Auto Cone Winders.

- Link Cone Winders.

- Two for One Twisters.

- Warping machines.

- Looms.

The Various Models of OHTC manufactured are

- ATC – B (With Belt Drive for shorter length Spinning related Machinery).

- ATC – S (Power Duct Type for longer length Spinning related Machinery).

- ATC – W (Power Duct Type for Weaving & its preparatory Machines) .

ATC – B Type

SIEGER OHTC - ATC – B Type, consists of suction cum blowing unit (BDU) which travels on straight railing arrangement in to & fro motion. The suction cum blowing unit consists of a built in backward curved centrifugal fan which creates the required suction and blowing.

The centrifugal fan rotation and to & fro motion of the suction cum blowing unit (BDU) is done by a tangential belt driven my an electric motor located at one end of the railing system in conjunction with a belt shifting mechanism located at suction cum blowing unit (BDU). The belt shifting mechanism is triggered automatically by spring plate fixed on to the railing with suitable adjustable fixing brackets.

The suction cum blowing unit (BDU) has suction hoses and blowing hoses suitably located based on the machine on which it is working with suitable nozzle arrange for blowing air as recommended by the Original Equipment Manufacturer (OEM). The suction hoses collect the waste from the floor and the same is filtered by a filter screen located in the suction cum blowing unit (BDU). The waste thus collected is discharged automatically when the suction cum blowing unit (BDU) reaches the end of the railing system through a discharge arrangement. The waste from the discharge arrangement will be sucked through a flexible hose connected to the pneumafil box of the machine on which it is working or to a Central Waste Collection system (CWCS).

ATC – S & W Type

The Various Models of OHTC manufactured are

- Straight Line.

- “U” Shaped Track (for working on two machines).

- “O” Shaped Track(for working on two machines).

- “S” Shaped Track ( For working on multiple machines).

The suction cum blowing unit consist of a built in backward curved centrifugal fan driven by a separate motor which creates the required suction and blowing. The travel of the suction cum blowing unit is done by separate motor in conjunction with a reduction worm gear box.

The suction cum blowing unit has suction hoses and blowing hoses suitably located based on the machine on which it is working with suitable nozzle arrange for blowing air as recommended by the Original Equipment Manufacturer (OEM). The suction hoses collect the waste from the floor and the same is filtered by a filter screen located in the suction cum blowing unit. The waste thus collected is discharged automatically when the suction cum blowing unit reaches the end / middle of the railing system through a discharge arrangement and a waste collection box. The waste from the waste collection box will be collected manually or sucked through suitable pipe line arrangement to a Central Waste Collection system (CWCS).

The suction and blowing unit has a built-in Micro-processor controlled control panel through which the drive motor to the unit can be manually started stopped or reversed using push button switches. The reversal of units at the track ends is done by a proximity switch which is fitted on the unit in conjunction with two sensing plates fitted in the track ends. The Micro-processor has other function like adjusting the time delay setting of the drive motor and fan motor & monitoring the current drawn by the drive & fan motors.

The power supply to the control panel is taken through a power duct which runs parallel to the entire track arrangement on the inner side for better stability.

The OHTC – ATC - S, can be supplied with Auto parking facility, anti-collision provision as Optional features depending on the machine on which it works / customer request.

Salient Features of SIEGER ATC

- Lighter weight and State of the Aero Dynamic Body design with elegant aesthetics for better performance.

- Special type closed power duct with Corner rib included and Increased Copper Groove size provides longer life to brushes.

- Special Copper with Zinc alloy strip with High wear resistance and better conductivity material to increase life of bus bar system.

- Power duct location is inside of the railing for better stability / life/ compactness as well as ensures total safety.

- The new improved design current collector with proper spring and brush guide system for better life.

- Metal graphite brush with extended length for better life& stability.

- Motor base mount & face mounting type for better stability and life.

- Latest version of Micro-processor controller for machine operation.

- New key pad duct free design on both sides for START, STOP and REVERSAL of the unit for better life.

- Interlocking design fan for better stability/performance..

Technical data

| System | ATC – B | ATC – S | ATC – W |

| Fan motor | 1.5 KW | 2.2 KW | 4.0 KW |

| Drive motor | NA | 150 W | 150 W |

| Fan Motor rpm | 2880 | 2880 | 2880 |

| Drive Motor rpm | NA | 1350 | 1350 |

| Blowing air volume | 2100 m3 / hour | 2400 m3 / hour | 2400 m3 / hour |

| Suction pressure | 200 mm wg | 230 mm wg | 230 mm wg |

| Travelling speed | 12 mpm. | 16 / 12 mpm. | 16 / 12 mpm. |