- Home

- Products

Lap Transport System - LTS

Lap Transport System - LTS

Lap Transport System

Introducing the SIEGER Lap Transport System—an innovative solution designed to automate the seamless transfer of laps/spools between the Lap Former and Comber machines. This cutting-edge system eliminates the need for manual intervention, ensuring precision and consistency in the handling process.

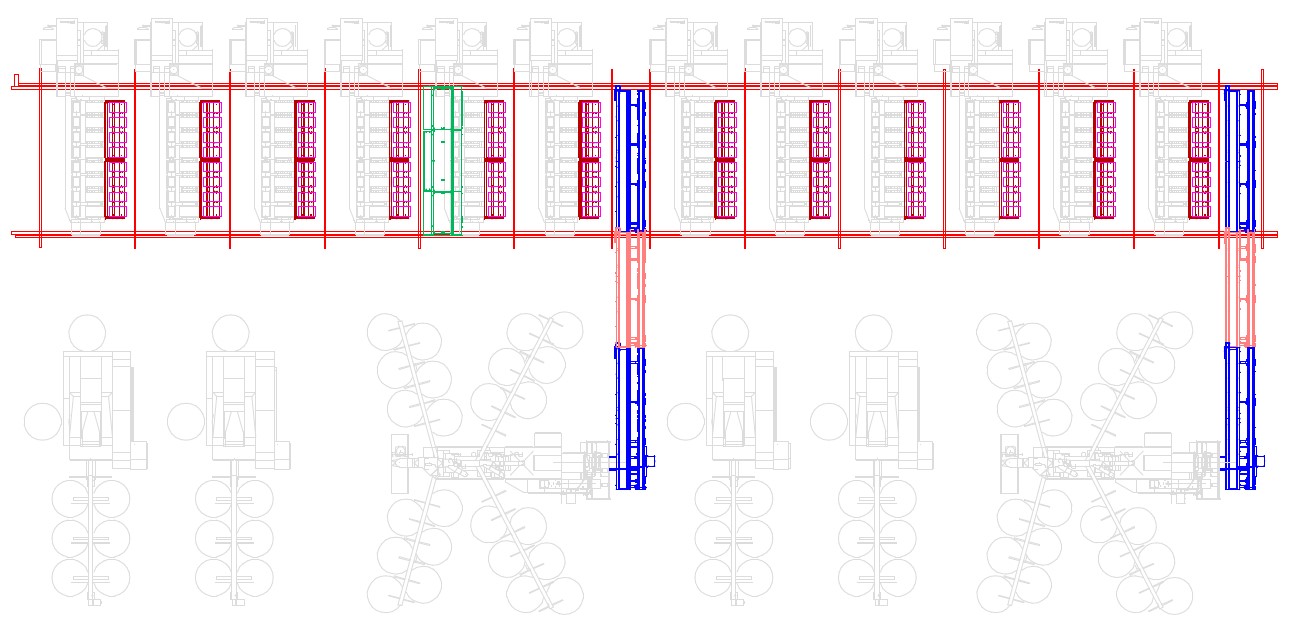

Reference Layouts

Experience unparalleled efficiency and quality assurance with our Comber Lap Handling System. Revolutionize your textile manufacturing process today.