- Home

- Products

Roving End Opener

Cleaning solutions - Roving End Opener

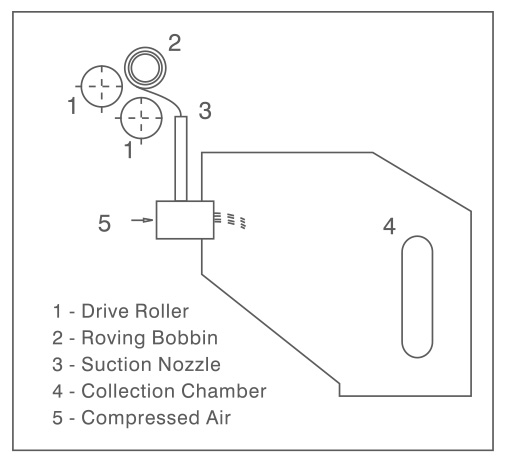

PRINCIPLE OF ROVING END OPENER - REO

Stripping of roving bobbins and opening of the roving ends is an important task in the spinning mills. Existing methods like cutting the layers of roving with knives and opening them directly in the blow room leads to damage to the valuable bobbin surface and also the fibres are subjected to fatigue which affects yarn quality.

SIEGER REO has been developed to ensure that no damage occurs to the bobbin surface and the fibres are also safely opened during the process. Rovings are removed by applying rotary movement to the bobbins and simultaneously evacuating the rovings. The evacuated rovings are throughly opened by applying compressed air current as a medium. This ensures that there is no physical damage to the fibre and bobbin as well. The roving can be effectively used as fresh raw material without addicting yarn quality. The operation is more scientific and requires less labour.

ADVANTAGES

- No physical damage to the Roving Bobbins.

- Gentle handling of the fibre.

- Less labour and highly productive.

- Saving of the valuable raw material.

- Very short payback considering the savings in labour and utilisation of the raw material.

FEATURES

- Fully Contained unit with stripping of the roving bobbins and opening of the fibre.

- Variable unwinding speed to suit various material and twist parameters.

- Simple operation and occupies less space.